We are equipped with OSU, EAGLES devices for arc metallization of ferrous or steel surfaces with molten carryovers of zinc, aluminuim and alloys, copper, etc.

Our workers are certified and qualified in the execution of the metallization process by International Organizations (NACE) and by the major international petrochemical industries.

The application process is divided into the following steps:

- abrasive blasting Sa 3, according to ISO 8501-1, of the substrate followed by careful dusting;

- carryover application (zinc, aluminum and their alloys, copper, etc..) of different thicknesses, ranging from 120 microns to 300 microns, depending on customer specification;

- application of a sealant. For a longer-lasting protection against corrosion (twenty years) the coating is reinforced with painting products.

In the processing stages are carefully controlled by our qualified inspectors: the degree of cleanliness, the roughness of the surface abraded, the thickness of fused carryovers applied, the coating adhesion, the thickness of the sealant and the finishes. The control equipment is properly calibrated and is always zeroed before use.

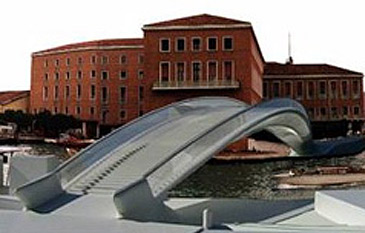

The activity takes place at our factory in Portogruaro (Venice) and at external places with mobile equipment.

Request us information about the process of metallization and about the protection of steel and ferrous structures with anticorrosive paint.

Metallizing treatments of metallic structures